Back

Product Parameter

| Items |

Parameter |

| Material Thickness0.2-0.6mm |

0.2-0.6mm |

| Forming Steps |

18steps |

| RollerMaterial |

45# steel, coated withChrome |

| Driving Motor |

11KW |

| Hydraulic Cutting Power |

7.5KW |

| Shaft Diameter |

75mm |

| Hydraulic Pressure |

10-12MPa |

| Power Supply |

380V/50HZ/3Ph (can be specified by user) |

| Cutting Type |

Hydraulic cutting, stop to cut |

| Tolerance |

±1.5mm |

| MaterialofCutting Tool |

Cr12 |

| Control System |

PLC with touch screen |

| Machine Dimension |

10800*1550*1650mm |

| Machine Net Weight |

5.5Tons |

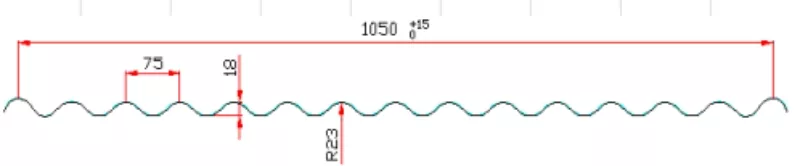

Profile Design Drawing

Machine Features

Xiamen Beenew Machinery works in manufacturing kinds of corrugated roof tile making machines, we can design machines according to buyer's requirements. Our corrugated roof making machines are adjustable design, such as galvanized sheet (or PPGI) width and thickness can be adjusted. The popular models like the 762mm corrugated design, popular used in Africa, and the 836 corrugated roof, are readily available in our factory for quick delivery. Producing Line speeds can be tailored to match specific production requirements, though higher speeds may increase costs.

Additionally, the galvanized sheet making machine’s design can be adjusted to meet different market requirements, we can provide durable machines to manufacturers. For ease of operation, we have made a manual cutter to shear coil heads or tails when needed, while the hydraulic cutting system provides automatic cutting after the corrugation has been completed. This combination of customization and automation makes our corrugated roof tile making machine a versatile and efficient solution for large-scale production.

Driven by an advanced PLC control system, the whole corrugated roof tile making machine operates automatically, managing essential processes like speed, sheet length, and the number of sheets produced.

Corrugated Sheet Installation on Engineer