Back

Product Parameter

| Items |

Parameter |

| Material Thickness |

0.4-0.6mm |

| Forming Steps |

12-18steps |

| RollerMaterial |

45# steel, coated with chrome |

| Driving Motor |

7.5KW |

| Hydraulic Cutting Power |

4KW |

| Shaft Diameter |

65mm |

| Hydraulic Pressure |

8-12MPa |

| Power Supply |

380V/50HZ/3Ph (can be specified by user) |

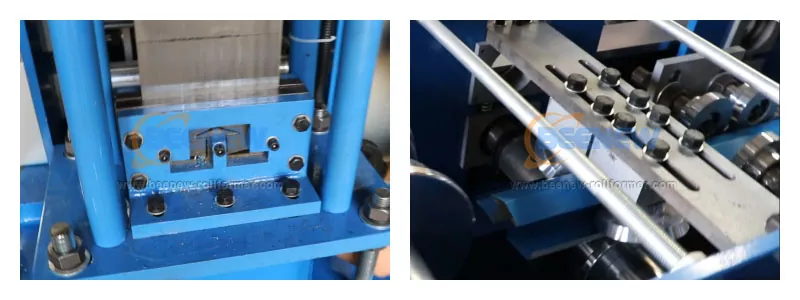

| Cutting Type |

Hydraulic cutting, stop to cut |

| Tolerance |

±1.5mm |

| MaterialofCutting Tool |

Cr12 |

| Control System |

PLC with touch screen |

| Machine Dimension |

9800*1350*1650mm |

| Machine Net Weight |

2.5Tons |

Metal siding roll forming machine Description

The metal siding roll forming machine is a production line that dedicated to the manufacturing of metal sheet or panel for facade siding or cladding.

The metal siding roll forming machine is an important family of roof siding roll forming machines. The wall panel can be divided into two kinds, one is for the Interior and the other is for Facades, and for most application, the metal sheet and panel must be concealed fastener.

Our metal siding roll forming machine features:

Working with galvanized, pre-painted or aluminum light gauge 0.4-0.6 mm

Fully “hands-free” automatic control by PLC system with touch screen

Cut to any length presetting in the program system

Follow cutting is optional with certain type of metal wall panel

Auto-stacker is optional to save labor cost

Perforated press is optional for the holes on the wall panel