Back

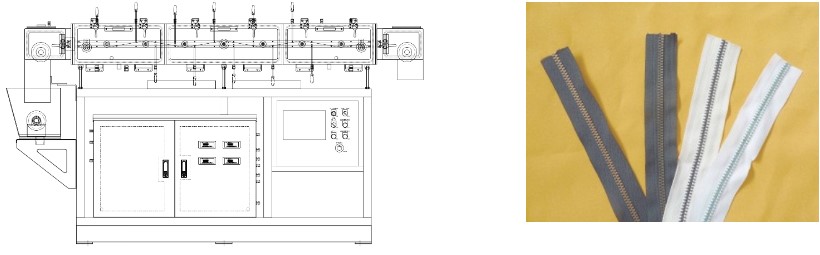

Roll-to-Roll Low-Temperature CVD System for Tarnishing Copper Alloy Fasteners

Overview: We have successfully established an atmosphere-pressure, room-temperature, roll-to-roll CVD processes for tarnishing copper-alloy fasteners and changing the colors of such fasteners. A high through―put and large-size apparatus for continuous CVD treatment of fasteners was fabricated for mass-production.

Characteristic:

- CVD tarnish of Cu fasteners based on oxidation of Cu alloy by ammonia gas

- By changing the gas density, variety of colors (brown, blue, green, and black) have been realized.

- Inert gas curtain flanges at both ends of CVD chamber were developed, allowing fasters with complicated shapes go through the CVD chamber but air not go in the chamber.

- A catalytic decomposition of used ammonia gas was installed, giving 0 ppm of residual ammonia.

- The total CVD treatment speed of the system reached Max 5m/min.

|